NPC852 is a programmable two-phase hybrid driver developed by Noketech based on RS485 bus. It adopts latest DSP technology of Ti and provides 6 input interfaces and 4 output interfaces,with 47 control instructions. It supports standard Modbus protocol and can be used as a single-axis controller with integrated stepping driver. The NPC852 adopt intergrated design that integrates motion control, motor drive, IO logic control, and touch screen HMI functions. Especially suitable for single-axis motor applications, which can save the controller and other units, simplify the control system.

Adoptive motor:42、57、60 series two-phase hybrid stepping motor.

Parameter setting switch description

1)Working (dynamic) current setting

Both current and micro step are set by program instruction.

2) Quiescent (static) current setting

The static current can be set by the instruction ACR=X. X=50 indicates that the static current is set as half of the dynamic current, and X=100 indicates that the static current is same as the dynamic current. In general use, X should be set to 50 to reduce the heat of the motor and drive and improve the reliability. About 2 seconds after the motor stops, the current is automatically reduced to about half (60% of the actual value), and the calorific value is theoretically reduced to 36%. The user can set the half-current start time and its value through the instruction.

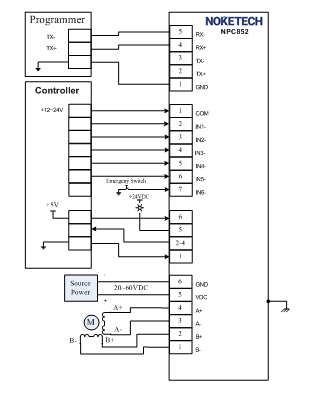

Typical wiring case

NPC852 typical wiring diagram

Electrical, Mechanical and Environmental Indicators

1. Electrical indicator

Description | NPC852 | |||

Min. | Typical | Max | Unit | |

Output current | 0.5 | - | 5.2 | A |

Working voltage | 20 | 36 | 80 | VDC |

Control signal input current | 7 | 10 | 16 | mA |

Operation speed | 0 | - | 3000 | RPM |

Insulation resistance | 500 | MΩ | ||

2. Using environment and parameters

Cooling mode | Free cooling or forced air cooling | |

Using environment | Places | Do not install near other hot equipment.. Please avoid the places with dust, oil, corrosive gas, high humidity and strong vibration, combustible gas and conductive dust are prohibited. |

Temperature | 0-50℃ | |

Humidity | 40-90%RH | |

Vibration | 5.9m/s2MAX | |

Storage temperature | -20℃~80℃ | |

Weight | 225g | |

3. The way to improve heat dissipation

1)The reliable working temperature of the drive is usually within 60℃, and the working temperature of the motor is within 80℃.

2) To reduce the heat of the motor and driver; it is recommended to select the automatic half-current mode when using that he current decreases by half automatically when the motor stops.

3)When installing the driver, please install it vertically and sideways, so that the heat sink teeth forms strong air convection; when necessary, install a fan near the drive for better heat dissipation, to ensure that the drive works within a reliable operating temperature range.

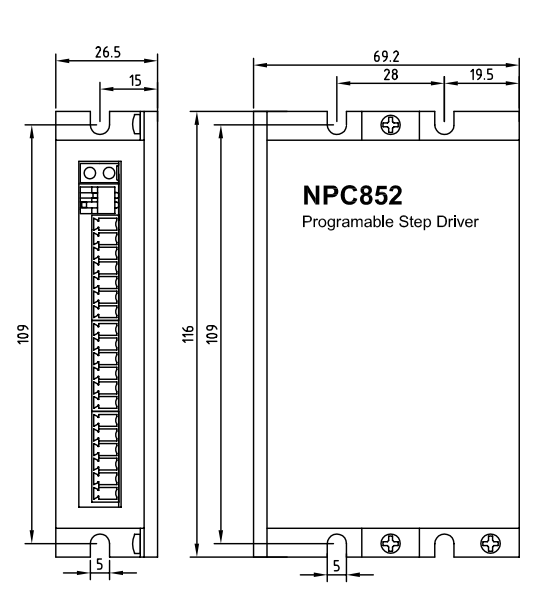

Mechanical installation drawing (unit: mm)