-

産品描述

-

電(diàn)氣參數

-

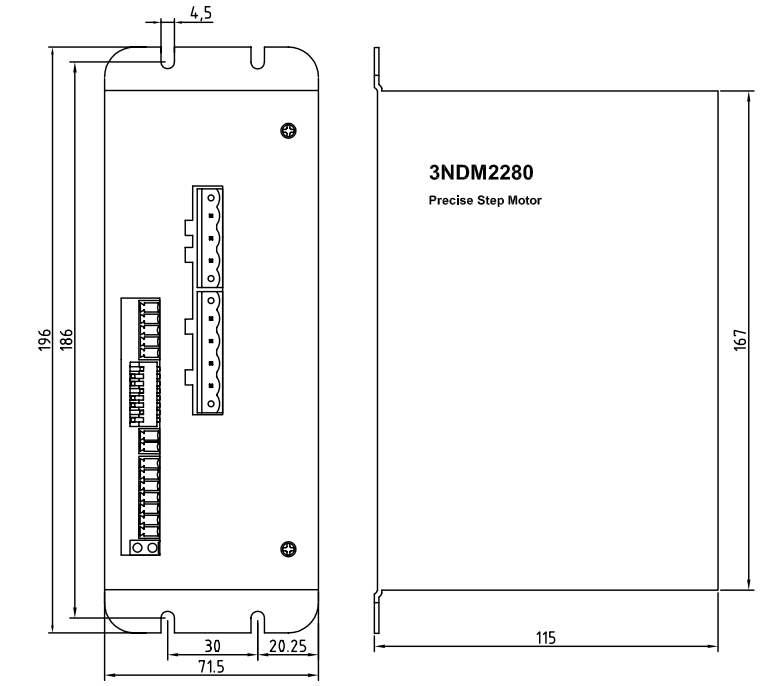

安裝尺寸

-

應用案例

Overview

3NDM580 is a digital three-phase hybrid motor driver for 110/130 three-phase hybrid motors launched by Noketech. It adopts the latest DSP technology of Ti, and taking advanced digital filtering technology,

anti-resonance technology and precision current control technology to make it realize precise smooth operation and extra low noise. It’s especially suitable for semiconductor, electronic processing equipment, laser processing, medical equipment and small CNC equipment.

Matched motor: 110,130 series three-phase hybrizstepping motor.

Parameter setting switch description

1)Working (dynamic) current setting

output peak current | output average current | SW1 | SW2 | SW3 |

Default | on | on | on | |

3.2A | 2.26A | off | on | on |

4.0A | 2.83A | on | off | on |

4.8A | 3.40A | off | off | on |

5.6A | 3.96A | on | on | off |

6.4A | 4.52A | off | on | off |

7.2A | 5.09A | on | off | off |

8.0A | 5.71A | off | off | off |

2) Quiescent (static) current setting

Static current can be set by SW4 DIP switch, on means that static current is the half of dynamic current, off means that the quiescent current is the same as the dynamic current.

In general use, SW4 should be set to on, so that the heat generation of the motor and the drive is reduced and the reliability is improved. About 400ms after the pulse train stops , the current is automatically reduced to about half (60% of the actual value), and the calorific value is theoretically reduced to 36%.

3)Micro step setting

3NDM2280 is a precision three-phase hybrid stepping drive, which can provide a maximum of 512 subdivision settings, the specific settings are shown as below.

Steps/REV | SW5 | SW6 | SW7 | SW8 |

Default | on | on | on | on |

400 | off | on | on | on |

800 | on | off | on | on |

1600 | off | off | on | on |

3200 | on | on | off | on |

6400 | off | on | off | on |

12800 | on | off | off | on |

25600 | off | off | off | on |

1000 | on | on | on | off |

2000 | off | on | on | off |

4000 | on | off | on | off |

5000 | off | off | on | off |

8000 | on | on | off | off |

10000 | off | on | off | off |

20000 | on | off | off | off |

25000 | off | off | off | off |

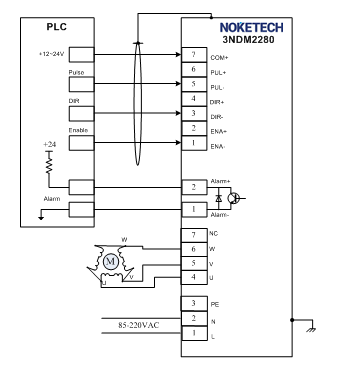

Typical Wiring Case

Typical application wiring diagram when adopts PLC control.

Typical application wiring diagram when PLC controls 3NDM2280

Notice:

1)When the user directly connects the 3NDM2280 to power voltage , the protective GND of driver must be reliable connected to the protective GND of the device. It is recommended that the user supply power to the 3NDM2280 through an isolation transformer. It is recommended that the isolation transformer use an input of 220VAC and an output of 180VAC.

2)The 3NDM2280 driver can only drive three-phase hybrid stepping motors.

Electrical, Mechanical and Environmental Indicators

1. Electrical indicator

Description | 3NDM2280 | |||

Min. | Typical | Max. | Unit | |

Output current | 1 | - | 8 | A |

working voltage | 85 | 110/220 | 230 | VAC |

Control signal input current | 7 | 10 | 16 | mA |

Pulse frequency | 0 | - | 200 | kHz |

Insulation resistance | 500 | MΩ | ||

Note: The control pulse frequency can be adjustable according to user application requirements. The max control pulse signal that can be received is 1MHz.

2. Using environment and parameters

Cooling method | Free cooling or forced air cooling | |

Using environment | Places |

Do not install it near other hot equipment.. Please avoid the places with dust, oil, corrosive gas, high humidity and strong vibration, combustible gas and conductive dust are prohibited. |

Temperature | 0-50℃ | |

Humidity | 40-90%RH | |

Vibration | 5.9m/s2MAX | |

Storage temperature | -20℃~80℃ | |

Weight | 1.35kg | |

3. Enhanced heat dissipation

1)The reliable working temperature of the driver is usually within 60℃, and the working temperature of the motor is within 80℃.

2) To reduce the heat of the motor and driver, it is recommended to select the automatic half-current mode when using that he current decreases by half automatically when the motor stops.

3)When installing the driver, please install it vertically and sideways, so that the heat sink toot forms strong air convection; when necessary, install a fan near the drive for better heat dissipation, to ensure that the driver works within a reliable operating temperature range.